Engineering services

Transferring engineering knowledge to our partners

Engineering support

SCT relies heavily on engineering and technology to ensure that tools are designed, manufactured, and optimized for their intended applications.

Creating solutions one company at a time

Engineering Processes

Tool Design & Optimization:

Creating and refining carbide tool designs to meet specific application requirements and enhance performance.

Material Analysis:

Studying the properties and behavior of various tungsten carbide compositions and binders to determine the best blend for specific cutting conditions.

Wear Analysis:

Investigating tool wear patterns to improve tool longevity and predict maintenance cycles.

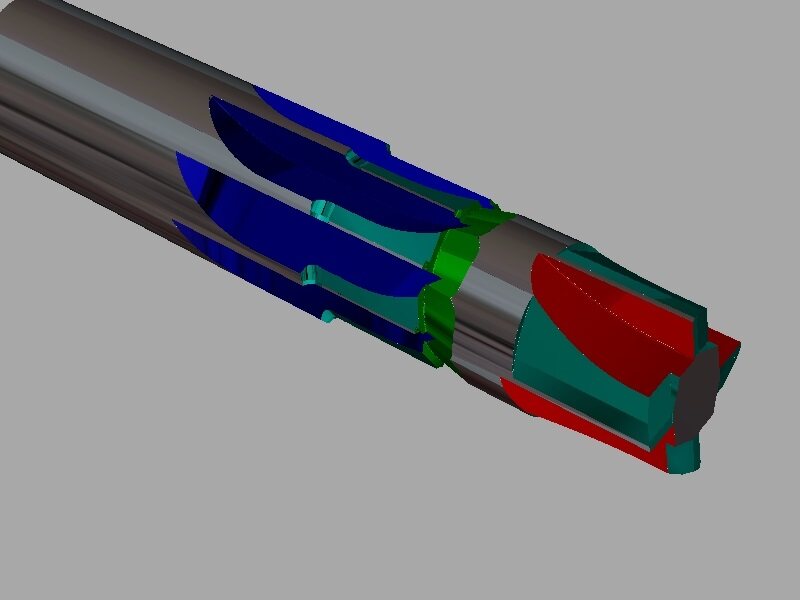

Simulation and Modeling:

Using computational tools to simulate cutting processes and predict tool behavior under various conditions.

Coating Development:

Engineering specialized coatings, like Titanium Nitride (TiN) or Titanium Carbonitride (TiCN), to improve tool life and performance.

Quality Control Engineering:

Developing and implementing rigorous testing and inspection procedures to ensure every tool meets or exceeds industry standards.

Custom Tool Solutions:

Collaborating with clients to engineer custom carbide tools tailored for unique machining challenges.

Thermal Analysis:

Studying the heat generation and dissipation during cutting processes to optimize tool design and coatings for temperature control.

Microstructure Analysis:

Using microscopy techniques to study carbide grain size, binder distribution, and other microstructural features to optimize toughness and hardness.

Vibration and Harmonics Analysis:

Investigating the dynamics of carbide tools in operation to minimize vibrations and improve cutting quality.