Regrind services

Service that can restore tools to original conditions

Re-Sharpen, Recondition

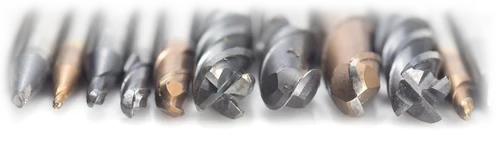

Carbide tools are meant to be re-sharpened several times and we cater specifically to your tooling needs to save you on average of 50%. We start by examining broken or underperforming tools to determine the causes of failure and implement corrective actions.

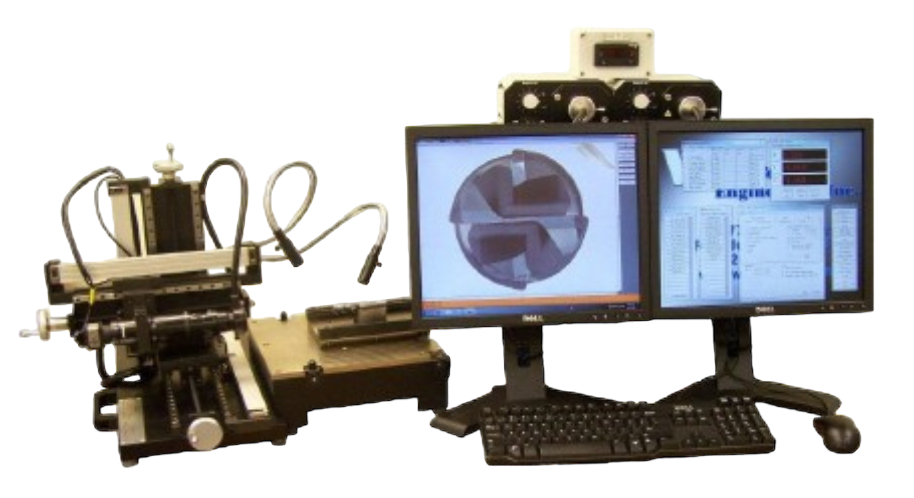

We Utilize high-resolution microscopes to study wear patterns, identify structural failures, and assess tool coating options. We then decide on improvements if necessary and incorporate the changes to our CNC programs.

By harnessing the latest in tool re-sharpening technology, we can repair and optimize any tool – from Custom, Standard or Hi- Performance. Let our service be the transformative difference for your tooling arsenal.

Performance guarantee

Tools restored to original condition.

Tools restored to original condition.

Surface treatments

Skills machinists will use decades of knowledg to apply the right geometry to match your needs.

Coating

Edge Hone

Diamond polishing